You are here: Home

|

|

|

You are here: Home |

|

Need Acrobat Reader for PDF documents? |

Hot and cold food smokingAs far as I know, the only page I failed to save from

the old site was the one from The Online Cookbook

on hot-smoked salmon. In fact, my adventures with

hot-smoking salmon came to an abrupt end when I smoked

£70-worth of fish for my daughter Sarah's wedding in

June 2013. Probably because I didn't clean out the Abu

Roken smoker thoroughly after each of the many batches,

my little meths burner managed to burn a big hole in the

heavy-gauge steel bottom. Always at a loss to buy presents for 'the man who has

everything', Patricia suggested that I might like a new

Abu smoker for my birthday in January 2014. We did some

research on the web and ended up starting me on a whole

new hobby! I'll try to recap the important things I've learnt

about hot-smoking, but I'll start with the new

venture... Getting into cold smokingWhen you hot-smoke food, it smokes and cooks at the same

time. After salt-curing for a couple of hours, my usual

portions of salmon fillet cook and smoke in about 20

minutes. Cold smoking - the process that produces what most of us

know as 'smoked salmon' - is quite different. For a

start, the food isn't cooked at all, so the salt curing is

needed for preservation as well as for flavour, and seems

from the contraductrory information I've found on the web

to go on for much longer. The food is then smoked at low

temperature - the cooler the better, it seems, to the

extent that people doing it in hot climates often put

trays of ice in the smoker! - for many hours. Clearly this

is a much more challenging process, and as I write this I

am right at the very beginning of the learning curve. I've

produced one 250-gram batch of smoked salmon, which I

judged to be over-salted and under-smoked, but which I ate

with some enjoyment last week. The equipmentPatricia felt that the cost of the replacement hot smoker

wasn't quite enough as a birthday present, so we agreed

that she could add a smoke generator for cold smoking and

I would build a housing for it. A bit more research

suggested that the racks and drip-trays I'd need might be

difficult to find without the housing, so I decided to buy

a cardboard one! No, really! I said you cold-smoke at a

low temperatrure, and to prove this you can do it in a

cardboard box. Well, actually two cardboard boxes,

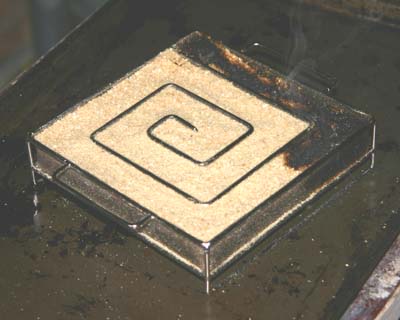

one inside the other. The product Patricia ordered is a ProQ Cold Smoke

Generator, bought from MacsBBQ

via Amazon. This is a remarkably ingenious piece of kit in

which wood dust will smoulder gently in a square spiral

made from steel rod and metal gauze. I dimly remember from

second-form science that a flame will not travel through a

fine gauze, and this device is a superb illustration of

that. Here's a picture taken this morning when testing

some smoking dust which I've had for a few years. If you

look very carefully you can see a curl of smoke towards

the right side of the picture.

The dust is contained in a square-spiral channel of

metal gauze. It is ignited by a tea-light placed in

a special holder under the beginning of the spiral

(top centre). The smoulder point then moves round

the spiral very slowly - this picture was taken

after about two-and-a-half hours. The other piece of equipment, which I bought from a company called SousChef, is the ProQ Eco Smoker. Basically, it consists of two currugated-cardboard boxes, one of which fits closely inside the other.

The ProQ Eco Smoker

The inside of the Eco Smoker

The upper drip tray and the three

racks rest on ingenious push-ins cut into the

corners of the inner box. The observant user will notice that the right-hand flap

is somewhat curly. This is due to water damage caused by a

burst pipe, which caused a rain shower in our garage just

after I'd done the first test of the smoker. Fortunately,

corrugated cardboard is easily repaired with ordinary

brown paper and PVA adhesive, and as I write the smoker is

ready for use. I am less concerned about this water damage than I could

be because I am already planning to build a more permanent

box, probably from MDF. This will allow better control of

the air flow, which is pretty poor with the cardboard

version - particularly with distortion from the water

damage - because the box top doesn't fit very well. The first testThis happened before the deluge. I used a nice tail

fillet of salmon which I salt-cured for a couple of hours

in the way I'd always done for hot-smoking: a couple of

hours liberally sprinkled - 'smothered' might be more

accurate - with sea salt. This was then washed and dried

with kitchen roll and smoked for about six and a half

hours, which is how long the bag of dust provided with the

smoke generator lasted. The resulting smoked salmon looked and felt pretty

convincing, and was more than edible, but was obviously

over-salted and under-smoked. I vac-packed 200 grams and

gave it to stepson Alistair, who assured me that he liked

his salmon nice and salty. I then ate the rest over a few

days. A slight delayThen came the deluge. On the Sunday morning Patricia went

out to the freezer in the garage and rushed back to report

a flood. When I got out there, I found well over a inch of

water on the concrete floor and water running down the

wall. Worse, the water had obviously run over the

tongue-and-groove pine flooring I'd laid to provide a

usable attic for storage. I put the lights on, hurried up

the ladder and discovered that the water was pouring out

of the polyurethane foam insulation covering a mains water

pipe that emerged from the house wall and ran along to

feed a tap inside the front door of the garage - very

handy for washing the car. There was a waterfall down the

brick wall and a strong jet onto the attic flooring. I

rushed down and closed the main stopcock under the

bathroom floor and this stopped the flow - but left us

with no water supply. Then I remembered that the excellent

plumber who had installed our new boiler and shower when

we moved in seven years before had put isolating valves in

the hot and cold feed pipes, conveniently just inside the

eaves loft door in our bedroom. I turned off the cold

water there, which meant that only our en-suite lost its

supply. On Monday our new plumber arrived and replaced a

length of pipe, which had been corroded by the cement

mortar where it went through the wall to the garage. It took the ProQ Eco Smoker box a few days tro dry out in

the conservatory, which Mother Nature graciously provided

with a little sunshine at the end of January. Back on taskWhile I waited for it to dry, I did a test with the oak

sawdust which had been lurking in the shed for two or

three years, a very small amount being used for hot

smoking. This was a gift from my fishmonger, Darren

Jelley, from whom I buy fish on Worksop market every

Wednesday. When I first rescued my Abu hot-smoker from the

shed, I bought a bag of the official wood dust on

Ebay, and I happened to mention this to Darren when buying

some salmon from him. He said that there was a smokery

next door to his premises in Grimsby and that he could get

me some dust from there. He was as good as his word, and a

couple of weeks later pulled a bag out from behind his

van. It was about the size of a hunredweight sack of coal,

and almost too heavy for me to manhandle across the car

park. Darren's passing shot was 'Let me know when you need

some more.' Not in this life, I thought! I had read during my recent web-wandering that dust for

cold smoking needs to be really dry, so I had put a

roasting tin full of Darren's dust in the oven at 100°C

for 24 hours. At 9:15 yesterday I loaded the cold smoke

generator with this, being very careful not to overdo it

and provide a bridge between the arms of the spiral, and

put a lighted tea-light in position. The dust quickly

started smouldering, and went on very nicely after I had

removed the tea-light until I checked it at 22:45 - twelve

and a quarter hours later. All the dust appeared to have

been consumed, but when I knocked the black residue out

into my workshop bin there were still some bright sparks,

so I had to put the bin outside for the night! During the day I had been experimenting with some of my

dried dust. The dust supplied with the smoke generator had

seemed finer than mine, some almost like flour, so I had

used our fine kitchen sieve to separate some of the dried

dust into two fractions. I had then gone on to put some in

the blender, but that had not managed the dust very well.

However, our small food-processor (if you've read The Online Cookbook

you'll know that we couldn't possibly have just one!) did

a much better job, with the dust spiralling round the

goblet violently and coming out much finer. Having established

e

arlier that the dust was fine just as it was, it was

probably pretty silly of me to use a 50/50 mix of the

dried and the processed dusts, but that is what I did this

morning (31 January 2014). It proved quite a lot harder to

light than the coarser stuff, and I was thinking of

emptying and re-charging the generator when it finally

caught. As I write, the smoker has been running for three

hours and is looking good. Finding useful informationI consider myself an expert web-user, skilled in finding

the information I'm looking for. I have to say that my

quest for hard information about salting and cold-smoking

has been one of the most frustrating ever. Many people

have committed their experience to websites, but very few

have produced anything clear. The salt-curing and smoking

times described vary wildly and I haven't found much

unanimity about cures. I was so frustrated that ended up

buying a book - not an e-book but one of those things with

printed paper pages! My cold smoker has stuff printed on the outside, amongst

it a web address: http://www.macsbbq.com/.

This would be my source of hard information. Unfortunately

the Guides section's link to cold smoking yielded

just two lines:

'Thanks a bunch!' I snarled when the page opened. I

hit the Contact link and used the form to

complain politely but bitterly. To my delighted

amazement, I got a phone-call within 24 hours from a

very friendly and helpful guy who directed me to their

Links page and particularly to this link:

He also told me a bit about Jo Hampson and her book Smoking Food at Home. By the end of the day I had ordered it from her Ebay shop and it arrived yesterday. I scanned, skimmed and searched, and found that it was certainly more informative and authoritative than any of the sites I'd found previously. I picked out a few pretty crucial bits of information and then dug the two hefty tail fillets of salmon I had bought from Darren on Wednesday out the fridge. Getting seriousThe first vital piece of information I picked out of

Jo's book was a simple cure for salmon: two parts salt

to one part brown sugar. I made a batch of this up

using mostly Aldi fine sea salt and dark muscovado

sugar. The second was that you only cover the fish with

something like 'a light covering of snow' rather than

the thick, opaque covering I'm in the habit of using

for a short cure before hot smoking (which was what

I'd used for the first cold-smoked salmon, which

explained the excess saltiness). So I did this, but

unfortunately the sugar was in lumps, although I'd

tried to squash them when mixing. Before I use the

rest I'll put it through the food processor. I used a lipped baking sheet which I sprinkled with

the cure before laying the fillets skin-side down and

sprinkling them with cure. That was at 15:00. I

covered the fish lightly with clingfilm and put the

package at the bottom of the fridge. At 22:45 I took

the fish out of the fridge (7 hours 45 minutes curing

time). There was a lot of liquid on the sheet but

still some of the cure, now very wet. I rinsed the fillets very thoroughly, rubbing with my

hands to dislodge any residual cure. Then I blotted

them off with plenty of kitchen roll and laid them on

a cooling rack on top of the rinsed baking sheet. This

went back in the fridge. The fish was much darker in colour than it had been

when fresh and was noticeably thinner and stiffer. I couldn't find any tea-lights this morning, so I

tried lighting the 50/50 coarse/fine dust in smoke

generator with my blowtorch. I did this again at 09:55

and this time it was smoking fifteen minutes later. I

have the impression that the coarse dust which I had

used for the test yesterday burns more reliably than

the mixture - probably because more air is trapped

between the particles. By 11:40 almost all of the first arm of the spiral

was burnt black. By 12:20 the smoulder point (my own

self-invented jargon!) was halfway along the second

arm and by 13:45 the third arm had started burning.

The first two add up to 240mm of a total 865mm. 240mm

in 3 hours 55 minutes calculates roughly to a total

burn time of about 14 hours 30 minutes. That would

have the smoke stopping at around half past midnight.

It is now 17:00. We will see - although I am unlikely

to stay up to see the finish if it is that late. I have one nagging concern: I see less smoke escaping

from the box than I remember during the first smoking,

so I wonder if the 50/50 mix is working well. On the

other hand, the dust used in the first smoking burned

away in six and a half hours - less than half the

anticipated duration of today's burn, so maybe the

smoke will simply work more slowly but ultimately with

the same effect. At 1700 the smoulder point is halfway along the fifth

arm - a total of 555mm in 7 hours. That gives a

projected finish in a total of 10.9 hours - about

21:00. I kept checking about every 90 minutes through the

evening, and at 22:40 (13 hours after the burning had

stabilised) I found that all the dust had burned away.

The salmon was dry on the surface, quite firm and a

very nice colour. I vacuum-packed one fillet for the

freezer and clingfilmed the other for the fridge. First taste - Saturday 1 February 2014This morning () I cut a thin slice off the fillet in

the fridge. The oak smoke flavour is good, but the

fish is over-salty. The control with a long cure has

to be the total quantity of cure applied. I'm

surprised that Smoky Jo hasn't suggested a range of

ratios. I'll have a close look at the book and maybe

find something in the recipe section (later: I

didn't). And next time the cure will have been broken

down in the food processor to allow more control over

the sprinkle. I think I also need to adopt a trick recommended by

many writers, which is - once the cure is finished and

the fish is rinsed - to slice off a tiny sample and

taste it. This should be quite safe if the curing has

succeeded. If the salt level is too low, I could then

sprinkle a little more cure mix onto the fish and give

it anotjher couple of hours. If it is too high, I

could give the fish a couple of hours in clean water

and taste, adding more soak time for excess salt or a

little more salting as above if too low. I suppose there's no reason which I shouldn't soak

and re-smoke a finished fillet if it really is too

salty.. We had a generous portion each off one of the fillets

at lunchtime today, on wheat crackers spread thickly

with Philadelphia cream cheese. The saltiness was

strong, but not enough to mask the smokiness or

otherwise spoil the experience. The texture was

excellent - quite dry, with none of the limp

gelatinous quality you get in some commercial smoked

salmon. I managed to cut fairly thin slices with my

Dad's wonderful old ham knife, but next time I'll try

Smoky Jo's trick of putting the fish in the freezer

for 40 minutes to firm it for slicing. Third smoking - Thursday 6 FebruaryI bought snother nice big tail fillet of salmon

yesterday from Darren and this morning I gave it a

really good rinse and rub in fresh running water. It

was then blotted thoroughly with kitchen roll. While it was drying a little, I put the rest of the

salmon cure in the small food-processor and gave it a

reaL pasting, but the little balls of muscovado sugar

only got smaller. They refused to disappear

altogether. Mayb e demerara would have been better,,, I sprinkled a thin layer of the cure on a lipped

baking sheet, laid the salmon on this, skin-down, and

then sprinkled the meat side sparingly with the cure.

At least the session in the processor had improved the

cure's sprinkling properties! I aimed for Jo's light

sprinkling of snow, not trying to cover the colour of

the fish. After four hours quite a lot of liquid had been drawn

out of the salmon but it still seemed quite flabby, so

I set the timer for a further two hours. At the end of the six hours there was still some salt

left on the flesh side of the fillet. The fillet was

quite stiff compared to how it was when raw. I decided

to rinse the remaining cure off at this point and took

a thin slice off the thick end to taste. The flesh was

quite salty but nowhere near as salty as the first two

batches. Going for broke, I decided to put the fillet on a

rack on a tray and air-dry it overnight in the fridge.

This was done at 17:00, giving about 16 hours drying

time before I can get the smoker on, which in turn

will allow 12-14 hours smoking before bedtime

tomorrow. I decided not to blot excess moisture off

the fillet but to leave it to dry naturally in the

hope that the much-disussed pellicle would form. This

sticky coating is supposed to give the fish a gloss

and to absorb more smoke. Incidentally, I watched a YouTube video

showing how to assemble and use the Eco Smoker and was

told to put the bottom drip tray in upside-down, so I

have done this for tomorrow's smoke. It certainly

makes it easier to slide the lit smoke generatior in

and out, and - on reflection - I can see that the

pocket of air under the tray will provide some

insulation between the burning dust and the cardboard

bottom of the box. Friday 7 FebruaryThe fillet was dry but tacky to the touch this

morning, suggesting that it had formed a pellicle. I put the fillet on a rack in the middle position of

the Eco Smoker. I filled the smoke generator with the coarse fraction

of the sieved wood dust (see Back on task

above) and lit it using a tea-light at 08:50. It was

smoking gently at 09:00 but by 09:15 it had gone out.

I re-lit it and it was going well at 09:35 and again

at 09:50. At 10:30 smoke was clearly visible emerging around

the top of the Eco Smoker - more visible than on the

second smoke with the 50/50 coarse/fine mix, which

suggests that the coarse dust will burn away more

quickly. That is logical as there will be more air

between the grains. A check through the slot at the

bottom of the box showed that the smoulder point had

reached about halfway along the first leg of the

spiral. A calculation based on this suggests that the

burn will last 18 hours, but I find this highly

improbably, especially as the dust seems to be burning

faster than before! At 12:35, with the second leg of the spiral just

finished, the maths was looking a bit more sensible:

240mm in 200 minutes gives 865mm in 720 minutes -

exactly 12 hours. So smoking should finish around

21:15 tonight. By 14:15 most of leg 3 had burned away,

and doing the same arithmetic with my fairly rough

estimate of just how much had gone I got a projected

finish time of 22:30. To be honest, I probably don't really need to check

the generator this often, but if it did stop burning

for any reason I'd like to get it going again as soon

as possible. Saturday 8 FebruaryI checked again at 16:45 and 20:00, when all but the

final leg of the spiral were burnt through. At 22:30,

when I was quite keen to get myself and the dog off to

bed, there was very little unburnt dust left, though

there was a healthy red-hot cinder. Rather than leave

this to burn out untended, I decided to empty the

generator and take the fish into the house. After

inhaling the aroma, which was much smokier than

previously, I clingfilmed the fillet and left it in

the fridge. This morning it feels quite firm and

stiff, and I can't wait for a taste! Sunday 9 FebruaryI put the fillet in the freezer for 40 minutes and

cut a couple of small slices just as a taster at

lunchtime today. I thought the fish was less salty

than the last batch but still quite strong, and that

the smoky flavour was very mild even after 13¼ hours.

Much more palatable than the previous fish, though. I've read somewhere that oak is one of the

mildest-tasting woods for smoking, although

'oak-smoked' seem to be the label on just about all

smoked foods. It would be interesting to taste fish

smoked with other woods. Patricia never stops talking

nostalgically about the wonderful smell of apple logs

burning on home fires in Normandy. Maybe when I prune

our apple tree I can dry some of the wood and saw it

with my circular saw. Or maybe I could just buy some

apple dust. We'll be taking down a largish cherry tree

grown from a stone soon - maybe that would be

interesting, too... Monday 10 FebruaryI had a proper helping for lunch today. It actually

seemed to cut more easily and controllably without a

spell in the freezer. The colour is a stunning orange,

there is no sign of free moisture or oil and the

texture is fine and even, as if the fish has really

been cooked by the cure. It looks as if any fat layer

between the flakes has been cooked away leaving a

lovely even texture. The previous batch had seemed a bit gristly, but this

was perfectly tender. Most interestingly, it was far less salty than

before, and less so - I thought - than the little

taste I had yesterday. I wonder if that top slice had

had the salt concentrated in it and over 24 hours the

salt had spread itself more evenly through the flesh.

Maybe a freshly smoked fillet needs to mature in the

fridge for a couple of days to even out the flavour

from the cure. Eaten on a sliced sourdough roll, buttered and spread

with Phildelphia soft cheese, the fish was quite

delicious. I intend to take a sample to the market for Darren to

taste on Wednesday. Wednesday 12 FebruaryAs it turned out, when I got to Darren's stall he

told me he had been unable to get the curing salt he'd

promised me from the Grimsby smoklehouse. He promised

it next week. And I, in the rush to get out to the

market, had forgotten to bring him a sample from my

latest salmon! Better luck next time... I bought a tail-end from a large fillet and cut

enough to fry for our dinner from the little end. This

left a much heftier piece of fish for the next

smoking: 975 grams. At 13:30 I sprinkled a modest

layer of the cure on a lipped baking sheet and put the

fish skin-side down on this. Then I sprinkled cure

thinly on the flesh side, rubbing it over with a fin

ger to even out the layer. The tray was clingfilmed

and put in the fridge with a timer set to six hours.

At the end of this all the cure had disappeared, so I

gave the fish another light sprinkle and two more

hours in the fridge. At the end of this time I rinsed the fish thoroughly

and blotted it with kitchen roll. It was much darker

in colour, quite stiff and now weighed 540 grame - 28

grams (1 ounce) less than before. I ran it under the

cold tap to wet it and left it on a rack in the fridge

to air-dry. Thursday 13 FebruaryAt 09:40 I took the fillet from the fridge and

weighed it. It had lost no weight at all. I filled the

smoke generator with the coarse fraction of wood dust

and it failed to light first time. I sprinkled a

little of the fine fraction over the ignition area and

it ignited OK second time round. As the box, somewhat warped from its accidental

shower a couple of weeks ago, had been leaking smoke

all round the lid, I wrapped the top in wide clingfilm

with a finger-sized hole poked in it over the hole in

the box lid. There was still smoke issuing from the

edges of the film, so this obviously wan't a brilliant

idea - clingfilm doesn't cling very well to cardboard. When I went back for a look at 10:15 the generator

was burning well, but without much visible smoke

escaping. Again at 11:00, burning was satisfactory but

there still didn't seem to be much smoke at the top of

the box. Over coffee I was pondering, and began to wonder

whether my wood dust was too dry, having been

baked in the oven for several hours and kept in

airtight containers ever since. So, at 11:50, I took a

spray bottle of clean water out to the garage. The

first thing that struck me was that there was quite a

bit more smoke than before, but I went ahead and gave

the generator a light misting anyway. Maybe next time I'll leave a gap in the ignition area

when filling with the coarse dust and mist this a

little more before filling the ignition area with dry

dust mix. Nothing untoward to report until 23:00, when I

decided to stop the burn and go to bed. I removed the

smoke generator but left the fish in the box for

tomorrow. Friday 14 FebruaryAt 10:00 I half-filled the burner. At 10:15 there was

a reasonable amount of smoke from the top of the box,

but at 11:30 I had to stop the smoking to go shopping

(I'm still not keen to leave the system burning when

I'm asleep or out!). I left the generator on the

garage step, but it raied quite heavily while we were

shopping. I refilled it with Darren's Grimsby wood

dust straight from the bag and re-lit it. At 15:15 I

noted that it was still burning but not producting

much smoke. At 15:45 I made the same observation -

dust not dry enough or particle-size mix wrong? I

microwaved a bowl of the dust on the simmer setting

for next time. At 19:00 I stopped the smoking, The

fish now weighed 520 grams - 48 grans down from the

starting weight, which was around 8% weight-loss -

nothing like the 20% recommended for preservation. This piece iof fish looks beautiful. We'll probably

taste it at Saturday lunch tomorrow... Monday 17 FebruaryIn fact we didn't get round to tasting until

lunchtime today. The fish is delicious: not over-salty

and with a distinctly more smoky taste than before.

The colour is rich and the flesh is tender. The first

batch that is a real pleasure to eat. The proof is

that Patricia ate quite a lot and declared it very

good indeed. There is a clear lesson in the curing process adopted

for this batch: don't over-salt, but if all the salt

disappears springkle some more and give it another

couple of hours. And as far as smoking goes, it seems

you can't oversmoke using the Eco Smoker. Wednesday 19 FebruaryI delivered the last 100 grams or so of last week's

smoked salmon to Darren when I went to the market this

morning. It was a bit of a wrench parting with the

fish, which has been really delicious, but I want

Darren's unbiased reaction - and anyway it was smoked

with the wood dust he gave me and he has promised me

some curing salt from the Grimsby smokehouse as well.

He still hadn't managed to get the salt, but as I'm

quite happy with my sea-salt and dark muscovado cure

that wasn't a problem. I bought another big tail

fillet - weight 778 grams - to use for frying and

smoking. On the way home I remembered that we wouldn't need

salmon for frying this week, so I'll be smoking the

whole piece. Oh dear! So the whole piece was rinsed thoroughly and blotted

dry. A thin layer of cure was then sprinkled on the

lipped baking sheet and the salmon was laid on this

skin-side down. The flesh side was sprinkled quite

lightly with cure, which I rubbed over with my fingers

before covering the fillet loosely with clingfilm and

placing in the bottom of the fridge. At 12:25 the

timer was set for six hours, the plan being to check

for any residual salt after this time. There was none,

so the fillet wase given a further light sprinkle and

two more hours of curing. It was then rinsed and left

wet on a rack in the bottom of the fridge. I wouldn't be able to smoke the fish until Friday, so

it would get a good long rest in the fridge after the

cure. Friday 21 FebruaryThe fish was left air-drying in the fridge until this

morning, when I got up early to start the smoking. At

07:00 I filled the smoke generator with untreated

Grimsby wood dust (no sieving or pre-drying) and put

it in the oven set at 110°C while I took George the

dog for his daily morning walk. I also put the fish on

its rack in the smoker. It was quite glossy -

apparently the indication of a good pellicle. At 08:20. having fed the dog, I lit the generator

using a tea-light. Unfortunately the wick was rather

short so the flam didn't reach the fuel. I re-lit is

at 08:35 with a blowtorch and it was smoking well at

08:45. By 09:45 two thirds of the first leg of the

spiral had gone and by 10:45 the second leg had

started burning and by 11:15 was half burnt. At 15:10

the first four legs were gone and the smoke was still

coming out at the top of the box. By 19:45 just the

last three short legs were left unburnt and by 22:55

the generator was burnt out and stone cold, so the

smoking probably ended around 22:00 - a total smoke of

over 13 hours. The fish was left in the smoker as the night was

pretty chilly. Saturday 22 FebruaryThe plan had been to re-start smoking early this

morning, but we decided to go to Retford and I'm still

not quite confident enough to leave the burning

generator unattended. So I re-charged the generator

with untreated Grimsby wood dust and put it in the

oven. By the time we were ready to leave the oven

r=had reached about 190°C, so I turned it off to cool

naturally. At 13:10 I re-lit the generator with the

blowtorch, as the tea-lights I have been using are

just too puny. The fire took first time and by 14:25

the first leg of the spiral had almost burnt away.

Smoking was still going well at 15:25, two and a

quarter hours after lighting. If I leave it to run

until bedtime - around 23:00 - the fish will have had

a total of over 23 hours. Which is just what happened. At 22:50 I took the

smoke generator out into the garden and emptied the

still-smouldering remains of the dust out. Then I

transferred the fish, which was very firm and a lovely

dark orange colour, on its rack into the garage fridge

for the night, leaving it unwrapped so that it could

continue drying. Sunday 23 FebruaryThis morning I brought the fillet into the house. It

was dry to the touch and very still - I could hold it

by the tail end and it hardly drooped at all. I

weighed it and found to my amazement that it had gone

from 778 grams to 520 - a reduction of 33%! Smokin' Jo

says the weight should reduce by at least 20% for the

fish to be properly preserved, so I guess this piece

will be safe to eat. This piece of fish has spent a lot longer uncovered

in the fridge than the previous one, as well as having

longer in the smoker, so the air-drying must have

worked really well. Patricia and I had some for lunch, and it was firm

and dry, yet moist enough, with a nicely balanced

flavour and certainly not over-smoked after almost 24

hours in the box. The last lot was very good, but this

was definitely better. The depressing thing is that

you carve the thinnest slices you can manage and eat

what seems like a very modest portion, yet the fillet

seems to shrink very rapidly! A lifetime's supply of wood and salt!Wednesday 26 February 2014This morning my visit to Worksop market was more than

usually fruitful. As well as a fine South Coast Dover

sole (identified by its pale skin) for tonight's

dinner and another salmon tail fillet for smoking, I

got Darren's positive feedback on his sample from the

week-before-last's salmon. And I got a very large present - a bag of salt as

used by the Grimsby smokehouse next door to Darren's

premises. I say very large because it turned out to be

a 25-kilogram bag. Darren never does anything by

halves! He very kindly volunteered to put it in the

car for me - provided I could get the car into the

little blind alley behind his stall. Aided by Google

Maps on the new phone and advice from a lady who

way buying fish, Patricia and I managed the

complicated feat of navigation and Darren carried the

bag and put it in the boot. We headed for home and unloaded the shopping. Duly

fortified by two cups of strong Costa coffee (the

roast and ground, sold in 200-gram bags at better

supermarkets - very good indeed!), I lifted the bag

out of the car boot and staggered into the hall, where

I laid it as gently as possible on the hall table. A

second leg got it to the kitchen table, where I

managed to decipher the white text on the pale blue

bag: 'Pure Dried Salt - The Salt Company, Nantwich,

Cheshire'. There was also mention of an

anti-caking agent called - rather ominously, I thought

- sodium hexacyanoferrate. The 'cyano' bit always

sounds a little dodgy, potassium cyanide being one of

the most lethal of poisons, but it actually crops up

in all sorts of perfectly innocent chemical compounds. So to Google and a search for 'salt company

nantwich', which threw up plenty of hits, the top

being 192.com and yielding this: 'We can offer Uk

mined and packed Salt from 750 gram tubs to 12.5kg

bags. We can offer Israeli mined and packed Salt

from 10kg to 25kg bags'. The fifth link was to

was The Salt

Company - FJ Need (foods). A quick wander round

the site found - among other products - Pure Dried

Salt and the following information: 'Pure dried

salt is a refined natural sea salt. The salt is

produced by solar evaporation of sea water in ponds

located by the Red Sea coast. The salt manufacturing

is done without chemicals thus obtaining the white

crystal glaze. It is a high quality food grade salt.

Production conforms to IS0 9001.2000.' Some of

the company's salts are approved for use in organic

food production, so I seem to have stumbled on a

plentiful stock of really good salt for my curing

experiments - not to mention all domestic use for

years to come! Many thanks, Darren! The use of the word 'mined' is a bit odd. You don't mine sea salt. However, Cheshire has been an important source of rock salt, which is mined, since Roman times. We called in at the village Co-op on the way home

from the market and I found a pack of bagels from the

New York Bakery Co (made under licence in nearby

Rotherham!). Straight from the packet they weren't

brilliant, but lightly toasted and spread with butter,

Philly cheese and last week's salmon? Pretty superb!

The crumb became softer and the crispness was perfect. Thursday 27 February 2014The tail fillet I bought from Darren yesterday was a

lot smaller than the previous one - just 398 grams.

Probably lucky, because I wasn't my usual obsessively

organised self and I made a mess of the curing! At 09:25 I applied the cure and filmed and fridged

the fish as before, setting the timer for six hours. I

was busy when it went off, and although I intended to

go back to it as soon as I had finished what I was

doing, I forgot and didn't remember it until 22:10 - a

12¾-hour cure! All the salt and sugar had gone but I

decided not to give the fish the usual 2 hours with a

little more cure - not least because I didn't want to

stay up for another two hours! I rinsed the fish and

put it, wet and uncovered, on a rack in the garage

fridge before retiring. The flesh was not as firm as

last time but noticeably more so than when raw, and

the colour had darkened from 'salmon pink' to a nice

dark orange. The weight had fallen to 384 grams. Saturday 1 MarchIt wasn't convenient to smoke on Friday, so I left

the fish in the fridge until this morning. I

pre-heated the smoke generator in a hot oven while I

walked the dog and lit it at 10:00 with the blowtorch

- tea-lights having provied rather ineffective. As

usual there were a few false starts, but smoking was

well under way within 20 minutes. The first day of

Spring was conveniently frosty so there would not be

any problems with temperatures high enough to promote

spoilage. At 22:10 the last short leg of the spiral

had been reached, so I left the smoker to burn out.

Again it was a frosty night so I wasn't worried about

leaving the fish in the smoker overnight. Sunday 2 MarchAfter the ignition hiccups yesterday I thought I'd be

clever and pile the dust quite high over the ignition

ramp. I lit this very easily with the blowtorch but

the adjacent leg of the spiral caught fire too! I blew

this out and sprayed it with water, but when I checked

at 09:00 both legs of the spiral were going strong -

the inner one smouldering at both ends so I was

actually getting three times the normal quantity of

smoke!  I scraped the L-shaped area clean, making sure I

got all the red-hod cinders out, and continued the

smoking. By 13:00 the smoulder point had almost

reached the break, so I filled this with dust. By

15:00 the 'repaired' section had burned away, and

smoking continued normally until shortly after

19:00, giving a time of 10 hours 50 minutes. Added

to yesterday's time, this made a total smoking

time of 22 hours 50 minutes. The fish on its rack

was transferred to the garage fridge. This 'error' has given me an idea: if I want to

give my fish a more intense smoking I could light

the dust at both ends and wait for the smoulder

points to meet in the middle. Or, as with the

mistake, light two separate bits to get three or

four smoulder points... Monday 3 MarchAt 09:00 I brought the fish into the house,

wrapped it in film and weighed it: 350 grams. It

was quite stiff (though not as stiff as the

previous fish) and a good dark orange colour, but

the weight loss was only 12% - nowhere near the

20% needed for long-term preservation. This must

have been due to the mess I made of the curing

stage. I haven't tried this fish yet, as we're are still

eating the previous piece, which we both agree is

excellent. Wednesday 5 March 2014

|

|